Florida Creates Cracking Test Task Group

With the future possibility of performance testing becoming a requirement for mixes in the state of Florida, members of the Asphalt Contractors Association of Florida (ACAF) decided to take a proactive step along with the Florida Department of Transportation (FDOT)

Focusing on the IDEAL-CT test for cracking, ACAF members formed a task group to lay out objectives and an action plan to present to fellow ACAF producer members. The current focus is to standardize testing, then begin testing “every day” mixes to determine what the baseline values are for these mixes. This data will be extremely valuable in the future to help influence the testing requirements if and when these are implemented in our state.

Steve McReynolds ATS Director of Operations and Tanya Nash, ATS Pavement Materials Engineer volunteered to lead this group whose initial meeting was last Wednesday, Oct 2nd. Following the meeting at Duval Asphalt’s production site, the group toured the ATS asphalt performance testing lab.

The group consisted of representatives from CTI Construction Testing & Inspection, Inc., Asphalt Technologies, Inc., Marathon Petroleum Corporation, FDOT, Ajax Paving Industries, Inc., Ranger Construction Industries, Inc., P&S Paving, Inc. and Hubbard Construction Company.

Changes to FAA Specification

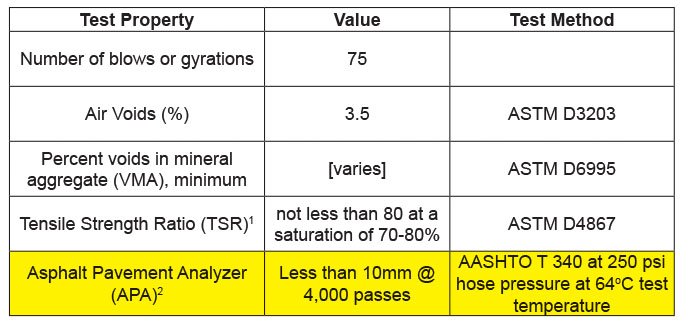

Recently the standard asphalt specifications for construction of airports were updated to include Asphalt Pavement Analyzer (APA) results. The December 2018 FAA Advisory Circular states “P-401:…added use of the Asphalt Pavement Analyzer…eliminating the need to run stability and flow when using the Marshall Methods and allowing the same asphalt design criteria in Table 1 to apply regardless of which mix design method is selected, Marshall or Gyratory.” Asphalt contractors must submit their asphalt designs meeting the following criteria:

Table 1 – Asphalt Design Criteria from FAA AC 150/5370-10H Item P-401:

The APA procedure has shown mixes that meet the requirements above perform well under aircraft loading. The APA is preferred on airport pavement projects serving aircraft greater than 60,000 pounds. If APA is not available in an area, compacted mix design samples may be sent to a laboratory that has an APA.3

The test method AASHTO T 340 describes a procedure for testing the rutting susceptibility of hot mix asphalt. Most commonly the wheel is tracked across the sample for 8,000 cycles. It takes approximately 2.5 hours to complete 8,000 passes, but samples must be conditioned for 6 hours prior to running the test.

ATS offers FAA asphalt mix designs, including TSR and APA testing all -in-house at its Jacksonville, Florida laboratory.

1Test specimens for TSR shall be compacted at 7 ± 1.0 % air voids. In areas subject to freeze-thaw, use freeze-thaw conditioning in lieu of moisture conditioning per ASTM D4867.

2 AASHTO T340 at 100 psi hose pressure at 64°C test temperature may be used in the interim. If this method is used the required Value shall be less than 5 mm @ 8000 passes

3 Excerpt from USDOT FAA Advisory Circular – Standard Specifications for Construction of Airports – 12/21/18

ATS On the Move – Where You Can Find Us

Recent Projects Completed for Asphalt Contractors by Country or State