Asphalt Binder Testing

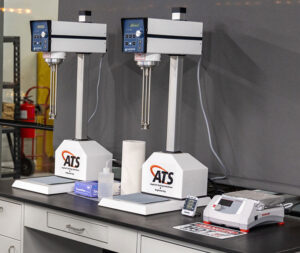

The ATS Binder Lab is AASHTO accredited and provides an array of asphalt binder and emulsion testing services. These test are completed for quality control of materials as well as for research and development projects.

Whether you are a contractor needing independent testing or a liquid supplier looking for a COA, our experienced technicians are on site to guide you through the process.

COAs / Referee Testing

The ATS binder lab technicians can provide a certificate of analysis (COA) for the asphalt binder to include full-specification testing results. COAs are typically required by the binder supplier to ensure and verify the supplied product meets target specifications enforced by transportation agencies to meet a given project’s requirements.

COAs are essential for several reasons:

- Quality Assurance

- Performance Prediction

- Regulatory Compliance

- Traceability

- Dispute Resolution

ATS technicians can provide COAs based on national or international specification requirements or based on a customized specification table.

Tests that may be included are:

| AASHTO M 320 | Performance-Graded Asphalt Binder | |

| AASHTO M 332 | Performance Graded Asphalt Binder Using MSCR | |

| AASHTO R 28 | ASTM D6521 | Accelerated Aging Using PAV |

| AASHTO R 92 | Evaluating the Elastic Behavior of Asphalt Using MSCR | |

| AASHTO T 44 | ASTM D2042 | Solubility Test |

| AASHTO T 48 | ASTM D92 | Flash by Cleveland Open Cup |

| AASHTO T 49 | ASTM D5 | Penetration |

| AASHTO T 51 | ASTM D113 | Ductility Test |

| AASHTO T 53 | ASTM D36 | Softening Point |

| AASHTO T 79 | ASTM D3143 | Flash Point with Tag Open-Cup Apparatus |

| ASTM D93 | Flash Point by PMCC | |

| AASHTO T 202 | ASTM D2170 | Viscosity by Vacuum Capillary Viscometer (Absolute Visc.) |

| AASHTO T 228 | ASTM D70 | Specific Gravity by Pycnometer |

| AASHTO T 240 | ASTM D2872 | Rolling Thin Film Oven Test (RTFO) |

| AASHTO T 300 | Force Ductility | |

| AASHTO T 301 | ASTM D6084 | Elastic Recovery by Ductilometer |

| AASHTO T 313 | ASTM D6648 | Bending Beam Rheometer (BBR) |

| AASHTO T 315 | ASTM D7175 | Dynamic Shear Rheometer (DSR) |

| AASHTO T 316 | ASTM D4402 | Rotational Viscosity (Brookfield) |

| AASHTO T 350 | ASTM D7405-20 | Multiple Stress Creep Recovery (MSCR) |

| ASTM D7173 | Separation Tendency of Polymer | |

| ASTM D7643 | Determining Continuous Grading Temperature & Grades |

Mix Support / Forensics / Failure Analysis

When things don’t go as planned or there is a failure at the roadway, how do you know where to start to diagnose the issue? Is there premature rutting or cracking? Poor density results? Slippage? How do you determine what’s in your binder after it has already been incorporated into the asphalt mix? Our team of professionals can remove that binder from the mix in the lab as well as complete forensic analysis on the road to pinpoint the problem area and recommend solutions.

| AASHTO M 320 / M 332 | ASTM D6373 | Performance Grade Verification |

| AASHTO M 320 / M 332 | Recovered PG Verification | |

| AASHTO M 320 / M 332 | ASTM D7643 | Recovered PG Determination |

| AASHTO R 29 | ASTM D7643 | Performance Grade Determination |

| ASTM D2172A | Centrifuge Extraction | |

| ASTM 5404 / D7906 | Solvent Recovery | |

| ASTM D8159 | Automated Solvent Extraction |

With the extraction and recovery process, our team can complete the testing required by the FAA P-632 specification for spray rejuvenators.

Formulations

Looking for a custom blend? Our asphalt binder experts can create a customized formulation adding polymers or additives through low and high shear blending and high shear blending to enhance binder performance. Some common additives include:

- Elastomers / Rubber (SBS, crumb rubber)

- Fillers (mineral filler, lime, fly ash)

- Chemical Additives (rejuvenators, warm mix additives)

- Plastics (polyethylene, polypropylene, polyvinyl acetate)

Product Development / Market Intro

Do you have a new product or technology you want to test in real world settings? Our binder lab is located on an asphalt plant’s property, so we have the capability to run research mixes through the plant for real world testing and handling. Let us find champions for your products; our relationships with state departments and contractors are valuable to connect you with the right teams.

- Concept Testing

- Formulation

- Product Optimization for Cost and Performance

- Mix – in the lab versus at the plant

- Field Performance

Are you new to the asphalt industry and not sure where your product fits in the market? We can help! Our customized Asphalt Industry Workshop familiarizes you with the asphalt industry and how to position your product in the market. Email of our Director of Engineering, Tanya Nash, for more details.

Our Process

1. Initial Consultation

When you contact us for asphalt binder testing, you’ll speak with our Director of Engineering to discuss the job and project needs. Once we fully understand your job requirements, we’ll present a detailed proposal that outlines the work and corresponding costs.

2. Send Product Samples

Ship us your binder or additive samples for us to begin the work.

3. Reporting

Our team will review detailed reports with your from the project.

4.Next Steps

Based on your project and test results, our experts will recommend steps moving forward.

Let's Talk Asphalt Binder

Ready to request binder testing for QC or research purposes? Simply complete the form below and we’ll contact you as soon as possible.