Asphalt Mix Design

The certified Mix Designers at ATS optimize the mix components for the most cost-effective mix designs to support our customers’ needs. Including Superpave, Marshall, FAA, Balanced Mix Design, and pavement preservation mix designs, our team has produced thousands of approved designs. Over the years asphalt mix design has evolved from a simple recipe approach to a more engineered procedure requiring our designers and technicians to test the designs with detailed analysis to ensure the volumetrics are optimized for stability and durability, using a balanced mix design approach to meet the pavement performance for rutting and cracking.

Superpave Mix Design

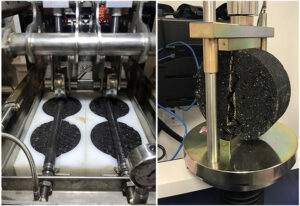

This method was developed as part of the Strategic Highway Research Program (SHRP) in the 1990s. It’s currently the standard mix design method in North America. Superpave considers traffic loading and environmental conditions and uses a gyratory compactor for mix designs. The gyratory compactor simulates the compaction that the mix will experience during construction and under traffic.

Superpave mix design relies heavily on volumetric properties of the asphalt mix. It also introduced performance-graded (PG) binders that account for temperature and aging conditions. It was initiated to construct more durable, long-lasting and cost-effective asphalt pavements that can cope with increasing traffic volumes, axle loads and varying environments.

Marshall Mix Design

Prior to Superpave, the Marshall mix design method was used. Although it is still used today in some states, it is most commonly used for fuel resistant airfield pavements. This procedure was developed in the 1940s, name after Bruce Marshall of the US Army Corps of Engineers. This method was developed as a means to identify the appropriate amount of asphalt needed in the mix and uses a Marshall Hammer for sample creation.

The Marshall method seeks to select the asphalt binder content at a desired density that satisfies minimum stability and range of flow values (Marshall Stability and Flow).

Federal Aviation Administration (FAA) Mix Design

FAA mix designs follow the specification requirements provided by the FAA for the design of asphalt mixtures used for airfields. The guidelines follow the P-400 specifications (P-401, P-403 and P-404). These mix designs require a high level of precision and quality control due to the unique load and safety requirements of airfields. Contractors must be familiar with these material and construction specifications before bidding on FAA projects, and the experts at ATS can help!

Balanced Mix Design (BMD)

Some states have implemented Balanced Mix Design (see the latest ATS webinar update here), and the asphalt mix designers at ATS optimize mixes in terms of cost-effective materials and performance. While Superpave designs have virtually eliminated rutting issues, balanced mix design helps address cracking while balancing the rutting performance. Balanced Mix Design considers mix aging, traffic, climate and the location within the pavement structure.

Balanced Mix Design also accounts for the quality of virgin and recycled asphalt binders and their interactions with different types of asphalt additives and asphalt modifiers. The goal is to create a mix that offers a balance between resistance to rutting (too much asphalt) and resistance to cracking (too little asphalt).

Pavement Preservation Mix Design

Pavement preservation is applying the right treatment to the right place at the right time. Pavement preservation mix designs are designed to maintain and extend the life of the existing pavement, minimizing deterioration, enhance performance, improve safety and meet motorists’ expectations. Some common pavement preservation treatments are

- Thin Overlays

- Chip Seals

- Microsurfacing

- Slurry Seals

Other Asphalt Mix Designs

The asphalt mix designers at ATS are available to create designs using the following design methodologies:

- Open Graded Asphalt Mixtures (ASTEM D7064 & FHWA Pie Plate Method)

- Stone Matrix Asphalt (AASHTO M 325)

- Superpave5

- Regressed Air Voids

Our Process

1. Initial Consultation

When you contact us for an asphalt mix design, you’ll speak with our Director of Engineering to discuss the job and project needs. Once we fully understand your design requirements, we’ll present a detailed proposal that outlines the work and corresponding costs.

2. Send Materials

Ship us your asphalt binder, aggregates and any additives required to design the mix.

3. Reporting and Submitting

Our team will review the completed mix design with you and send it to you or the approving owner or agency.

Let's Talk Asphalt Mix Design

Ready to request a custom asphalt mix design? Simply complete the form below and we’ll contact you as soon as possible.