Asphalt Consulting

Asphalt consulting services include a broad range of technical, strategic, and management support functions, all designed to enhance the efficiency, safety and sustainability of asphalt-related projects. We work with contractors, pavement owners, additive and modifier suppliers, state and local governments and liquid suppliers in a variety of areas of asphalt consulting.

Some services include:

- Project Planning & Management

- Asphalt Engineering Analysis

- Pavement Evaluation & Analysis

- Specification Development

- Product Development & Approval

Pavement Project Planning & Management

Whether it’s a new pavement project or you have aged asphalt that needs repairing or replacing, our ATS professionals can help guide you. From RFP development to scope of work and project oversight to pavement inspection and testing, our team of experts has years of experience working with paving projects. Our team will work with you to ensure your project is completed on time, within budget and meets the required quality standards.

Our team can also provide maintenance planning for your project to help extend the asphalt pavement’s lifespan and reduce long-term costs.

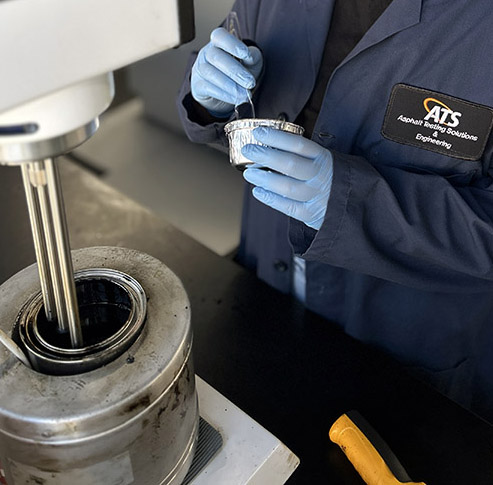

Asphalt Engineering Analysis

When things don’t go as planned or there is a failure at the roadway, how do you know where to start to diagnose the issue? Is there premature rutting or cracking? Poor density results? Slippage? Our team of professionals can complete forensic analysis on the road or at the plant to pinpoint the problem area and recommend solutions.

When you find yourself in the middle of a job and your materials are found to be non-compliant, an Engineering Analysis Report (EAR) may be required. Our in-house professional engineer, backed by our team of experienced specialists will conduct a thorough analysis of your asphalt materials or product and determine possible causes of non compliance:

- scope of work

- develop testing plan

- testing, analysis and reports

- professional recommendations

Pavement Evaluation & Analysis

Pavement evaluation is important for many reasons. It’s crucial to know the current pavement condition, because the results will determine your next steps – and budget! Does your asphalt require repairs or a complete mill and repave?

What if your new asphalt doesn’t look up to par? Our team members can provide expert opinions following a pavement analysis if you have concerns about the work completed.

Of course, ensuring safety is the number one priority! Our evaluations can identify safety issues such as poor skid resistance or large potholes. Watch our video to learn how to identify common pavement distresses!

Specification Development

Specifications outline the quality standards the asphalt mix and final pavement must meet as well as ensure consistency across different batches of mix and sections of pavement.

Sometimes when new material, processes, or procedures take place, specifications may be created or adjusted. Some of these types of specifications can be temporary, experimental, and flexible, depending on the owner. They provide a structured way to innovate and improve in the field of asphalt materials and paving while still maintaining control over quality and performance.

Specification review or development might be used when introducing a new type of asphalt mix, additive or modifier, paving technique, or asphalt performance test. When used for a trial, the data and feedback are reviewed for future adjustments and refinement of the specification in preparation for being adopted as a standard specification.

Contact us if you have a new product or technology to test and need specs written – we can help!

Product Development & Approval

Developing a new product that has potential to enhance the performance of asphalt mixtures is only one step of the process. The technical asphalt materials and construction knowledge of the ATS team can help develop a research plan to look at the potential benefits of your new product from proper dosage, formulation, and balanced mix designs to application and performance.

Continued industry involvement locally and nationally allows the ATS team to stay informed regarding new technologies, market trends and state requirements. Our expertise and knowledge enable us to develop plans that will optimize the product and allow for it to shine during the approval process in the client’s desired areas.

Perhaps you already know your product works and need a third-party lab to test your product for agency approval. Our knowledge of agency product approval processes allows you to target regions rather than one agency at a time.

Have a new product or technology but not really sure where it fits in the market? Our Asphalt Industry Workshop includes a market analysis custom made relative to your product or technology. Click here for more details about the workshop.

Our Process

We’ve been helping asphalt contractors, pavement owners, additive producers, state and local governments and liquid suppliers for years. Each consulting request is unique, but our process remains the same:

1. Initial Consultation

When you contact us with an asphalt question, you’ll speak with our Director of Operations or Director of Engineering to discuss the project needs.

2. Proposal

Once we fully understand the job requirements, we’ll present a detailed proposal that outlines the work and corresponding costs.

3. Schedule Work and/or Site Visit

Upon approval of the proposal we’ll schedule your project and provide the project scope and timeline. If required we will schedule a site visit at this time.

4. Reporting

Detailed reports of daily work will be provided for your records.

Let's Talk Asphalt Consulting

Need some help in the asphalt world? Simply complete the form below and we’ll contact you as soon as possible.