Background: Generally speaking good asphalt pavements should last approximately fifteen years before they need to be replaced. There are many ways to extend the life of asphalt pavements through different pavement preservation techniques, but what is really happening to the asphalt during the aging process?

On a basic level, asphalt mixtures consists of aggregates and asphalt binder, and as the asphalt ages, it becomes brittle from stress, weather, time and oxidation. By bringing life back to the asphalt binder or “regenerating” it, the life of the pavement can be prolonged.

Asphalt binder includes asphaltenes and maltenes. Maltenes are highly soluble, oily fractions. Asphaltenes are long, spindly carbon chains that develop during the asphalt aging process and replace the maltenes. Think of maltenes and asphaltenes as a plate of spaghetti and meatballs. When there is not enough sauce (maltenes) combined with the spaghetti noodles (asphaltenes) it becomes hard to move the noodles around; the meal will be really dry if there is an overabundance of pasta noodles (asphaltenes) on your plate and not enough sauce (maltenes). Asphalt binder needs maltenes to stay fluid and flexible.

Blacklidge Emulsions demonstrated the effects of its age-regenerating surface treatment ReGenX® on an older asphalt pavement. ReGenX® is an emulsified rejuvenator developed to chemically restore aged asphalt binder by penetrating existing asphalt pavement surface layer adding years of additional service life. ReGenX® is sprayed onto existing asphalt pavements through a traditional emulsion distributor. The emulsion penetrates the pavement surface as it breaks (evaporates the water), absorbing into the aged and oxidized asphalt.

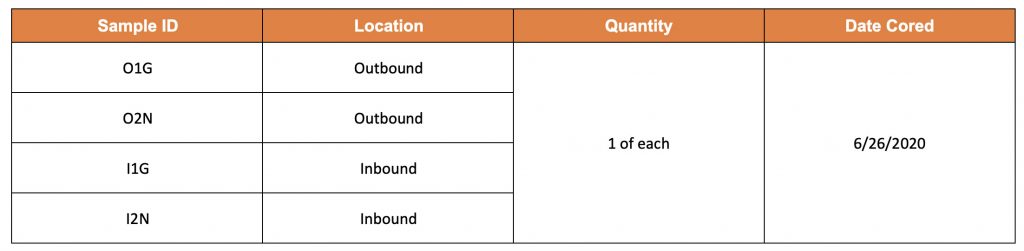

Project Scope: Blacklidge Emulsions and Asphalt Testing Solutions & Engineering (ATS) partnered with paving contractor Duval Asphalt to perform a product demonstration on the roadway entering Duval Asphalt’s Green Cove Springs plant. The road consisted of two asphalt mixtures placed at separate times. The mixtures were identified as having Georgia and Nova Scotia Granite aggregate. ATS technicians took cores from the pavement section prior to the ReGenX® application. The original viscosity of the asphalt mix was determined using two cores from the inbound lane and two cores from the outbound lane on the roadway. A core from each mixture was taken for both directions. (Table 1)

• Inbound Georgia (I1G) and Inbound Nova Scotia (12N)

• Outbound Georgia (O1G) and Outbound Nova Scotia (O2N)

Table 1. Original (Untreated) Viscosity Core Sample Information

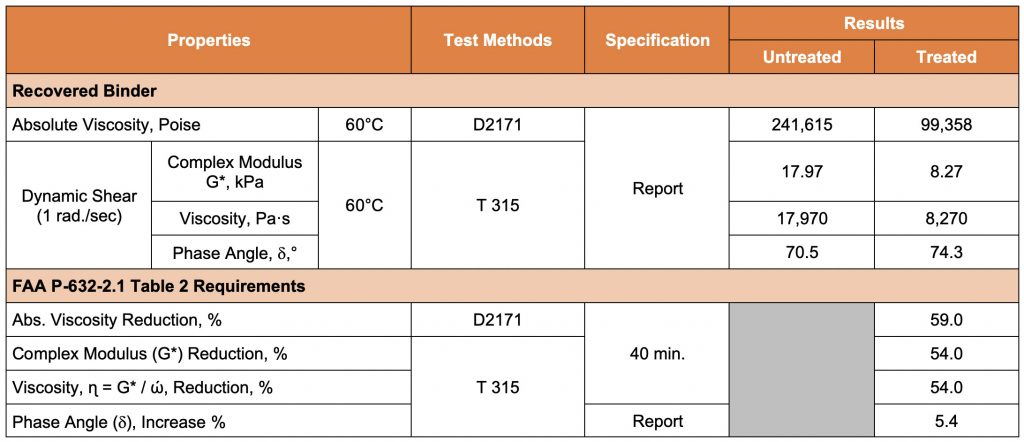

Both sets were processed and tested per the FAA P-632 requirements. The average of these results is listed as “Untreated” in Table 3.

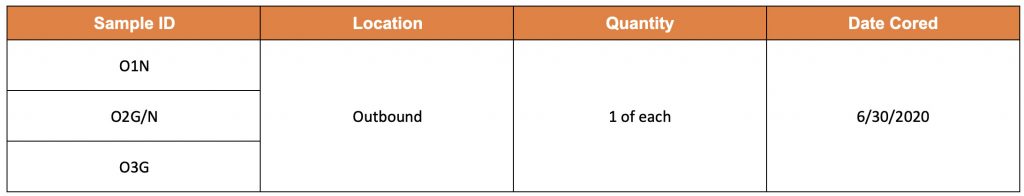

On June 30, 2020, Blacklidge Emulsions performed a product demonstration using ReGenX® on the outbound lane only of the roadway. It was applied at a 0.07 gal/yd2 application rate. The inbound lane was left untreated for performance comparison at a later date. One hour after the application was completed, ATS technicians took three cores from the outbound lane. (Table 2)

• Outbound Nova Scotia (O1N)

• Outbound Georgia & Nova Scotia (O2G/N) – core taken at joint of the two mixtures

• Outbound Georgia (O3G)

Table 2. Treated Viscosity Core Sample Information

Due to tracking on the roadway, Blacklidge Emulsions advised the cores sit for a minimum of 72 hours. After one week of being stored in the ATS laboratory, the cores were prepped and tested per FAA P-632 requirements. The test results are shown in Table 3 as “Treated.” The viscosities and complex modulus reduction met the requirements for a pavement three years or older per FAA P-632 Table 2.

Table 3. Summary of Test Data

Conclusion: The cores treated by ReGenX® showed a significant reduction in viscosity. The application is recommended to be applied to asphalt pavements every four to five years. At this time follow up testing can be performed to compare the performance of the treated and untreated sections of the roadway.