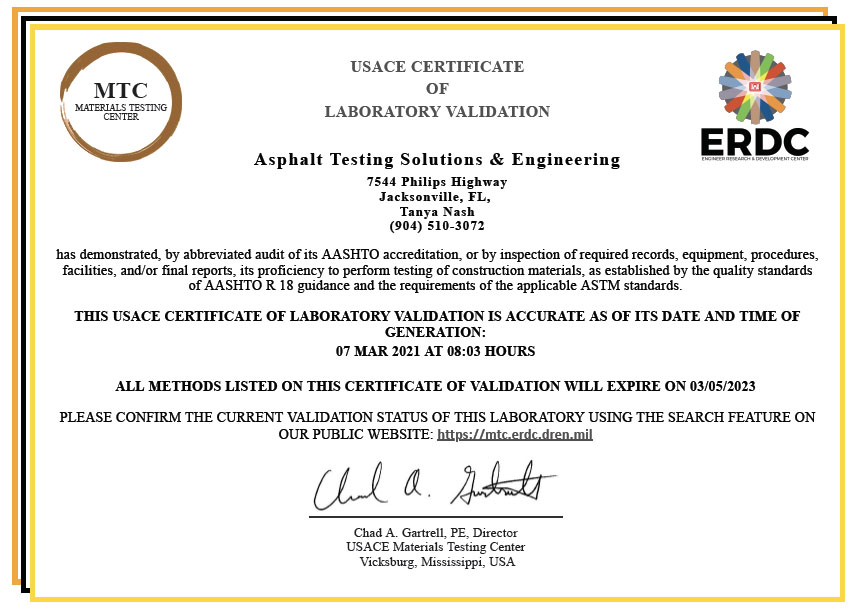

Asphalt Testing Solutions & Engineering (ATS) is pleased to announce it is officially a United States Army Corps of Engineers (USACE) Validated Laboratory for construction material testing! This means ATS is equipped, staffed and qualified to perform asphalt materials testing for the USACE, just as it is for asphalt contractors. ATS is an accredited asphalt lab, and the USACE certification states that ATS “has demonstrated, by abbreviated audit of its AASHTO accreditation, or by inspection of required records, equipment, procedures, facilities and/or final reports, its proficiency to perform testing of construction materials, as established by the quality standards of AASHTO R18 guidance and the requirements of the applicable ASTM standards.

ATS is validated to perform the following test methods for USACE:

| Aggregate | C 29 – Opt – Unit Weight and Voids in Aggregate |

| Aggregate | D 75 – Opt – Sampling |

| Aggregate | C 117 – Req – Material Finer than 75 µm (No. 200) Sieve |

| Aggregate | C 127 – Req – Specific Gravity & Absorption in Coarse Aggregates |

| Aggregate | C 128 – Req – Specific Gravity & Absorption in Fine Aggregates |

| Aggregate | C 131 – Opt – Los Angelas Abrasion Resistance on Small-Size Course Aggregates |

| Aggregate | C 136 – Req – Sieve Analysis of Aggregates |

| Aggregate | C 142 – Opt – Clay Lumps |

| Aggregate | E 329 – Opt – Standard Specification for Agencies Engaged in Construction Inspection, Testing or Special Inspection |

| Aggregate | C 535 – Opt – Los Angelas Abrasion Resistance on Large Size Course Aggregates |

| Aggregate | D 546 – Opt – Sieve Analysis of Mineral Filler |

| Aggregate | C 566 – Opt – Total Moisture Content |

| Aggregate | C 702 – Opt – Reducing Samples to Testing Size |

| Aggregate | C 1252 – Opt – Uncompacted Void Content of Fine Aggregate (as influenced by particle shape, surface texture and grading) |

| Aggregate | D 2419 – Opt – Sand Equivalent Value |

| Aggregate | D 3666 – Opt – Minimum Requirements for Agencies Testing and Inspecting Road and Paving |

| Aggregate | D 4791 – Opt – Flat and Elongated Particles in Coarse Aggregate |

| Aggregate | D 5821 – Opt – Percentage of Fractured Particles in Coarse Aggregate |

| Bituminous | E 329 – Opt – Standard Specification for Agencies Engaged in Construction Inspection, Testing or Special Inspection |

| Bituminous | D 979 – Req – Sampling Bituminous Paving Mixtures |

| Bituminous | D 2041 – Req – Theoretical Maximum Specific Gravity & Density (Rice) |

| Bituminous | D 2171 – Req – Viscosity by Vacuum Capillary Viscometer |

| Bituminous | D 2172 – Req – Quantitative Extraction |

| Bituminous | D 2726 – Req – Bulk Specific Gravity and Density |

| Bituminous | D 3203 – Req – Percent Air Voids |

| Bituminous | D 3549 – Opt – Thickness or Height of Compacted Asphalt Mixture Specimens |

| Bituminous | D 3663 – Req – Random Sampling of Construction Materials |

| Bituminous | D 3666 – Opt – Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials |

| Bituminous | D 4402 – Opt – Viscosity Determination of Asphalt at Elevated Temps Using Rotational Viscometer |

| Bituminous | D 4867 – Req – Effect of Moisture |

| Bituminous | D 5404 – Req – Asphalt Recovery by Rotary Evaporator |

| Bituminous | D 5444 – Req – Mechanical Sieve Analysis of Extracted Aggregate |

| Bituminous | D 6307 – Req – Asphalt Content of Hot-Mix Asphalt by Ignition Method |

| Bituminous | D 6390 – Opt – Determination of Draindown Characteristics in Uncompacted Asphalt Mixture |

| Bituminous | D 6752 – Opt – Bulk Specific Gravity and Density of Comp Asphalt – Automatic Vacuum Sealing |

| Bituminous | D 6925 – Req – Relative Density of Asphalts by Superpave Gyratory Compactor |

| Bituminous | D 6926 – Req – Preparation of Bituminous Specimens Using Marshall |

| Bituminous | D 6927 – Req – Marshall Stability and Flow of Bituminous Mixtures |

| Bituminous | D 6931 – Opt – Indirect Tensile (IDT) Strength of Asphalt Mixtures |

| Bituminous | D 7175 – Opt – Determining Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer |

| Bituminous | D 7405 – Opt – Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using Dynamic Shear Rheometer |