Your parking lot and roads are one of the largest expenses of your property, and what you don’t know about your pavement could be costing you money!

Commercial & Private Work

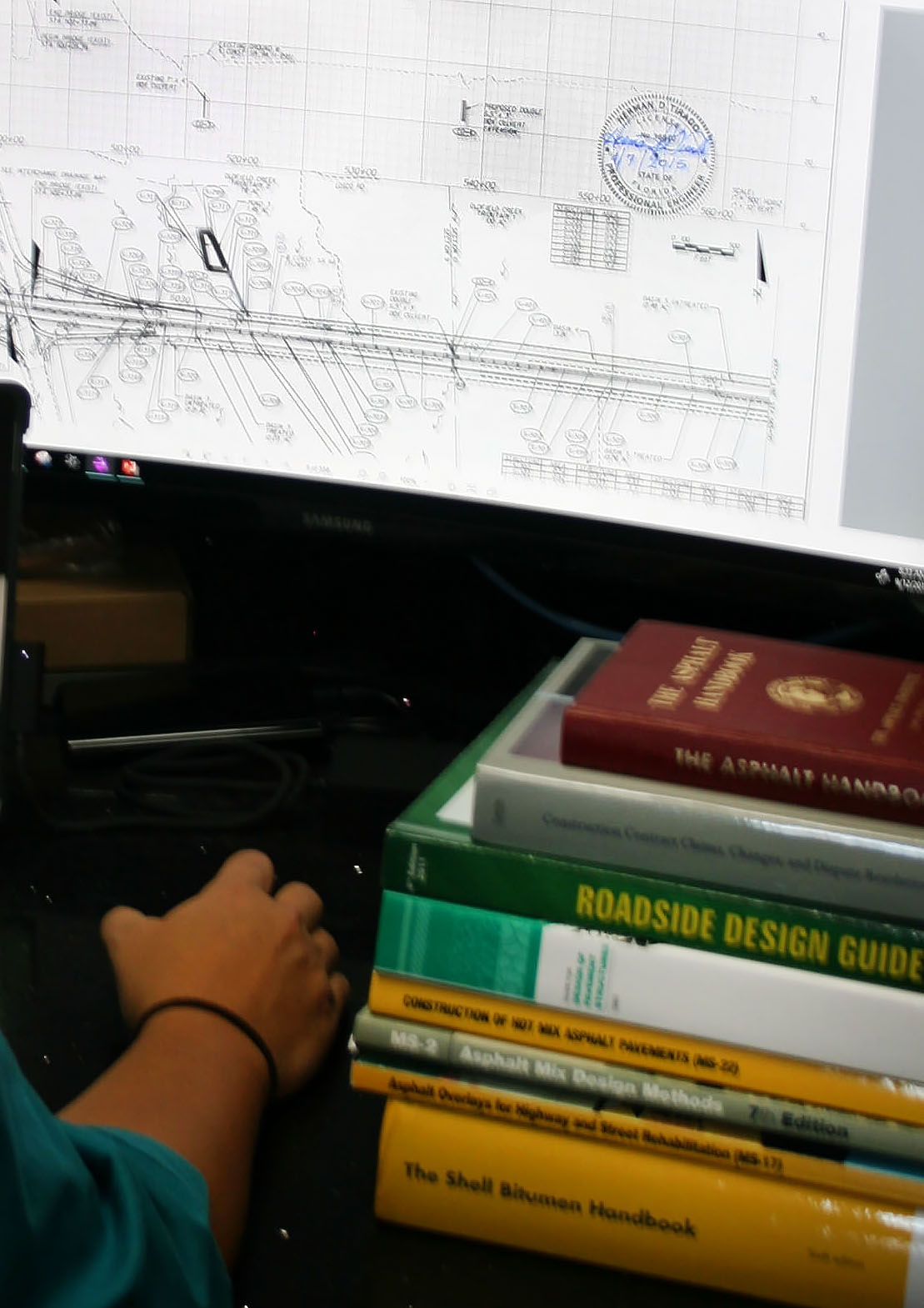

Asphalt Quality Control

Asphalt Manufacturing

Asphalt Quality Control responsibilities belong to the asphalt contractors and is in place to show they provide quality products with results for acceptance. ATS technicians can assume asphalt quality control responsibilities and will test the asphalt as it is produced to ensure the end product meets state or customer specifications. The process may include:

- Properly collecting samples from the trucks immediately following load-out

- Monitoring actual mixing temperature at the plant

- Verifying liquid asphalt content

- Identifying volumetric properties of compacted asphalt specimens and the specific gravity of the asphalt mix

Asphalt Paving

During construction ATS technicians test asphalt as it is placed in the field. The process may include:

- Verifying proper rolling patterns are employed

- Monitoring roadway temperatures

- Calculating tack, dilution and spread rates

- Checking density after asphalt paver lays the asphalt mix and after each roller passes

- Cutting core samples to check for actual density results

- Ensuring acceptable quality practices are followed

Asphalt Quality Assurance

Quality Assurance is the continued evaluation of planning, design and the development of plans and specifications to provide confidence that the product or facility will perform to standards. This is provided through an unbiased, independent review of all operations, procedures and equipment used in the asphalt quality control process. This is achieved by:

- Observing and inspecting procedures during production and placement

- Split sample testing

- Evaluating performance and qualifications of the technicians

- Verifying equipment is calibrated and in proper working condition

- Conducting project oversight

- Reviewing reports and results for accuracy per the project’s requirements

Asphalt Consulting

When you know it is time to give your parking lot or roads some attention but aren’t quite sure where to start, we can help prepare a Request for Proposal (RFP) for you. Our technical writers will compose an RFP for you to send qualified vendors.

Roadways, runways and parking lots are expensive assets. Not asking for the right product makes them even more expensive. Receiving a long-lasting pavement begins with a thorough evaluation and ends with good construction. To help ensure that you are receiving the best product, allow our in-house professional pavement engineer and experienced specialists to assist you in any of the pavement service lifestyle.

Pavement Evaluation + Action Plan + Asphalt Specifications + Project Management = Performance Pavement

Asphalt Testing Solutions & Engineering offers turnkey services that include consulting on new technologies to troubleshooting failures like cracked asphalt and everything in between for your commercial paving project.

We can help with:

- RFP Development and Assistance

- Pavement Evaluations (new, maintenance, forensic)

- Pavement Management Plans

- Asphalt Specifications Development

- Project Oversight (QC/QA)

- Asphalt Inspection & Testing Services

- Litigation Support / Expert Testimony

Engineering Analysis

If there is an issue with your asphalt during any point in its lifecycle, our in-house professional pavement engineer can conduct a thorough analysis. If the issue is an asphalt materials failure at the plant, we can analyze the project data to determine which areas need to be addressed.

If there is a deficiency with your asphalt later in its life cycle, such as cracked asphalt, our professional engineer can complete a forensic investigation to diagnose the problem and provide options to current the issue.

There are times when an Engineering Analysis Report (EAR) is required. Typically, this occurs when an asphalt material or product is non-compliant. If this happens, our team of experts will conduct a thorough analysis of your asphalt materials or product and determine possible causes of non-compliance:

- Scope of Work

- Develop testing plan

- Testing, analysis and reports

- Professional recommendations

Asphalt Mix Design

The certified Mix Designers at ATS incorporate the correct mix components for the most cost-effective mix designs to support our customers’ needs. Including Superpave, Marshall, FAA and pavement preservation mix designs, our team has produced over 1000 approved designs. Over the years mix design has evolved from a simple recipe approach to a more detailed analysis procedure and our designers and technicians will test the designs to ensure the proper volume of air voids and asphalt binder are mixed for stability and durability, as well as use a balanced mix design approach to meet the fine line between rutting and cracking.